Links

Links to India, Part I: Best QC Practices and "Westgard Rules"

October 2005

Dr. Westgard recently returned from a four-city tour of India. As a way of thanking his gracious hosts, and letting the rest of us know what he was doing, he provides some extra details on his time in this burgeoning laboratory marketplace.

- Perspectives

- Summary of Best QC Practices and "Westgard Rules" presentation

- Links to Best QC Practices and "Westgard Rules"

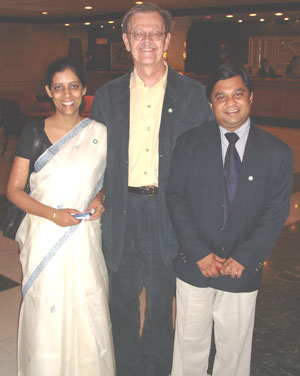

I’ve just returned from a week of workshops in India and want to express my gratitude for the warm reception from the many laboratory scientists who attended the QC Meet-2005 seminars in Mumbai, Kolkata, Chennai, and Delhi. These programs were sponsored by Bio-Rad Laboratories and I also want to thank their representatives, two of whom are shown in the picture here (Sonal Pandya, left, and Balram Parath, right).

I’ve just returned from a week of workshops in India and want to express my gratitude for the warm reception from the many laboratory scientists who attended the QC Meet-2005 seminars in Mumbai, Kolkata, Chennai, and Delhi. These programs were sponsored by Bio-Rad Laboratories and I also want to thank their representatives, two of whom are shown in the picture here (Sonal Pandya, left, and Balram Parath, right).

It is an unbelievable experience to meet so many people who turn out to be long-lost friends. By that I mean people with whom there is a certain familiarity, a common sense of purpose, and certain shared values, like old friends. What is strange is that we have never met before, but have become acquainted through the scientific literature and more informally through the Internet, particularly through Westgard Web. We have established a basis for our friendship even though we’ve never been formally introduced.

Perhaps this is most evident in India where parents are especially concerned about the relationships of their family members. However, this experience is not limited to India. I have found long-lost friends in China, Korea, Slovakia, and many other countries that I have visited. I think this occurs because people who are interested and dedicated to quality develop a certain philosophy and set of values that become the basis for how we work and how we behave. That work ethic and behavior are the basis for our friendship. Whatever the reason, it is a wonderful experience!

Perspectives

India has a population that is 10 times that of the US in a geographical area of 1/3 the size of the US. Healthcare laboratories are often privately operated, which means there are a large number of laboratories. One figure quoted was 40,000. The directors of these laboratories are MDs and PhDs with specialized backgrounds in laboratory medicine

Laboratories are very interested in ISO certification and there was a lot of discussion of ISO 15189 and its requirements. One reason for the ISO direction is that healthcare will likely become an international commodity and there is an opportunity for “boutique” healthcare services in India, just like that occurring in other parts of Asia.

Laboratories are very interested in ISO certification and there was a lot of discussion of ISO 15189 and its requirements. One reason for the ISO direction is that healthcare will likely become an international commodity and there is an opportunity for “boutique” healthcare services in India, just like that occurring in other parts of Asia.

Of particular interest to me, there were large numbers of MDs and PhDs who attended these QC seminars. The interest in QC seems much greater than would be found among doctorate level scientists in the US. Quality is obviously an important professional responsibility in the rapidly developing marketplace of healthcare laboratories in India.

In this context, I presented discussions of (I) basic QC practices, including details of multirule QC, as well as (II) the relationship between the quality requirement of a test and the actual QC rules and numbers of measurements necessary to assure the desired quality is achieved. To provide additional background materials, we are posting summaries of these presentations on Westgard Web, along with links to other explanatory materials on our website. Part I will deal with “Best QC Practices and Westgard Rules.” Part II will cover “Clinical Quality and Analytical Quality Control.” Part III in this series will cover the presentation on ISO by Greg Cooper of BioRad US, shown above with Dhiren Wagle, BioRad manager India.

Summary of “Best QC Practices and Westgard Rules” presentation

When one considers the quality of QC itself, the simple definition of quality, i.e., “do the right thing right,” provides some important guidance. “Doing the Right QC Right” is an alternate title for this presentation. The first right has to do with using the right control rules and the right number of control measurements. The 2nd right has to do with implementing QC in the right way, which means paying attention to the selection of control materials, the calculation of the means and SDs and control limits, the interpretation of control results, and the actions that should follow.

|

| Lab Professionals in Kolkata |

The history of statistical QC in laboratories begins with Levey-Jennings charts and the use of 2 SD control limits (or 12s rule). Unfortunately, many laboratories today still use 2 SD limits, which give rise to a high level of false rejections (5% for N=1, 10% for N=2, 14% for N=3). These false alarms corrupt the QC system, often leading to practices of repeating the controls until the controls again and again until they are finally within limits. Use of 3 SD limits (13s rule) solves this problem, but also reduces the rejections for real errors.

The approach with multirule QC is to reduce false rejections by using the 12s rule only as a warning rule, then build up the error detection of the 13s rule with additional rules for inspecting the data, i.e., 22s, R4s, 41s, 10x. Contrary to public belief, I don’t believe there is any one set of magic rules. Labs need to use the rules appropriate for the precision and accuracy of their methods and the quality required for each test. With high precision analyzers, single-rule QC is often adequate; with immunoassay analyzers, multirule QC is often advantageous.

The “Right QC” can be determined with the aid of Sigma metrics. Given a quality requirement in the form of an allowable total error (TEa) and knowledge of the precision (CV) and accuracy (Bias) of a method, the calculation is simple: Sigma = (TEa – Bias)/CV. This Sigma metric is closely related to the metric for critical systematic error, SEcrit, that describes the size of the systematic error that must be detected by the QC procedure to assure the desired quality (TEa) is achieved. That allows us to make use of an existing QC planning tool – the critical-error graph – and show the relationship between Sigma and the QC necessary to detect important errors. Once you know Sigma, you can make a good assessment of the QC that is needed, with the following “rules of thumb”:

- 6 sigma, any QC will do, just don’t use 2 SD limits;

- 5 sigma, use Ns of 2 or 3 with single-rules such as 13s or 12.5s;

- 4 sigma, use Ns of 4, with multirules;

- less than 4 sigma, use Ns of 6 with multirules, all the QC you can afford!

- 3 or less, look for better analytical methods!

You can see that there is no one magic QC procedure. Laboratories need to select the right QC on the basis of the quality required for the test and the precision and accuracy observed for the method. Simple methodology, such as the sigma rules of thumb, provides good guidance. Optimal QC designs are possible with computer support, such as the EZ Rules 3 program from WQC and the Westgard Advisor from Bio-Rad.

Links to Best QC Practices and "Westgard Rules"

To provide a more complete background and reference materials for the 1st lecture, here are the relevant links to materials on Westgard Web.

- The concept of statistical QC is described in a lesson on “QC: The Idea” . This lesson also provide links to other lessons, which are part of our book on Basic QC Practices. There’s a short course in QC here for those who want to review basic practices.

- The basic concepts of multirule QC and the definitions of control rules are found in the lesson “Multirules and ‘Westgard Rules’: What are they?”.

- Best practices for adapting multirule QC to your own laboratory methods and applications are discussed in the lesson “Best Practices for ‘Westgard Rules’”

- There’s also a discussion of “worst practices”, i.e., things to be careful about or even avoid.

- The original multirule paper that was published in the Clinical Chemistry journal is available at www.westgard.com/mltirul3.htm.

- Data calculation tools, such as a QC Calculator, QC Plotter, QC Simulator, and QC Trainer. These are intended to be learning tools, not production tools, and you will find the QC Calculator useful for understanding cumulative means and SDs, the QC Simulator useful for learning how errors affect the observed distributions of QC results, and the QC Trainer for teaching personnel how to interpret QC data.

- Some background on “power curves” – those detector response curves that show the probability of rejecting runs have different sizes of errors – can be found in the lesson “Power Function Graphs”.

- The application of “Sigma metrics” for selecting the “right QC” procedures is described in the lesson “CLIA Final Rule: Appropriate QC Procedures”.

- The design of optimal QC procedures, as supported by our EZ Rules3 automatic design program. Note that this program is our PC version of the Bio-Rad Westgard Advisor technology.

- A hardcopy paper that summarizes much of this material and approach, the paper “Internal Quality Control Planning and Implementation Strategies,” published in Ann Clin Biochem 2003;40:593-611.

Your feedback will be appreciated!

|

|

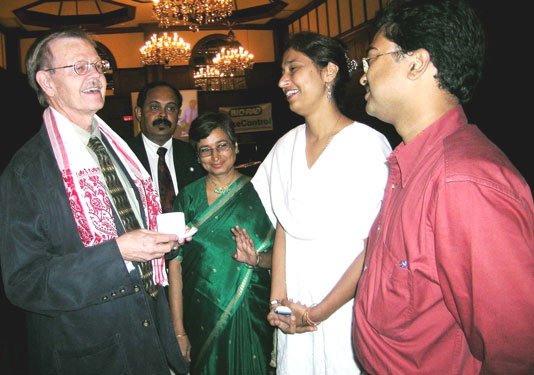

Dr. Thuppil Venkatesh on the left and Dr. Sandeep Sen on the right. Dr. Venkatesh is known as the "lead (Pb) man of India" and is also the head assessor for lab certification |

This is a new form of posting on this website. The message is addressed to a specific audience who were participants in an educational program. Our goal here is to supplement that program and provide support for those participants who have become more interested in the topic and want to gain a more in-depth understanding of the ideas. We appreciate your comments on whether or not you find this posting to be useful, as well as any suggestions on how we might make this more useful to you.

For any readers who were not participants in this program, we are also interested in your comments. Do you find it useful to see a summary of such a presentation, along with links to more detailed materials? Is this a useful format for organizing materials on this website around topics that might be of interest? Let us know.

James O. Westgard, PhD, is a professor of pathology and laboratory medicine at the University of Wisconsin Medical School, Madison. He also is president of Westgard QC, Inc., (Madison, Wis.) which provides tools, technology, and training for laboratory quality management.